Vertical Roller Mill Maintenance LinkedIn

Vertical roller mills (VRMs) are vital pieces of equipment in cement plants and are popular in new installations due to their high efficiency. ... Vertical Roller Mill Maintenance Published on ...

WhatsApp)

WhatsApp)

Vertical roller mills (VRMs) are vital pieces of equipment in cement plants and are popular in new installations due to their high efficiency. ... Vertical Roller Mill Maintenance Published on ...

Vertical Roller Mill Routine Maintenance. To prolong the service life of vertical roller mill reduce the number of repair we must do a good job in vertical roller mill routine maintenance specific steps may refer to the following maintenance method Often listen to vertical roller mill .

Each 1000h measurement of a millstone, lining board wear and record the grinding roller. The weekly check a vertical mill pressure accumulator. Regular inspection center frame, nozzle, guide vane, the spray pipe and other mill accessories. The above is about the vertical roller mill routine maintenance .

Maintenance Details Of Vertical Roller Mill Summary. As the name implies, the presentation of vertical roller mills is more threedimensional, so the lateral footprint is smaller. Because the vertical roller mill is a intensive device that integrates crushing, grinding and grading systems. The internal equipment is complete and has good stability.

Vertical roller mill has also become a special equipment to promote the increase of steel slag grinding project. The vertical roller mill equipment in steel slag plant. The vertical roller mill is a kind of equipment for solid waste residue project. The grinding mill .

Maintenance Details Of Vertical Roller Mill Summary. As the name implies the presentation of vertical roller mills is more threedimensional so the lateral footprint is smaller. Because the vertical roller mill .

Therefore, ease of replacement and regeneration is a major feature of the mill. The MVR mill has a modern hydraulic system used in operation and for maintenance alike. With this new type of roller suspension, the rollers can be swung out of the mill in a controlled way – for ease of replacing the onepart grinding roller .

Therefore, ease of replacement and regeneration is a major feature of the mill. The MVR mill has a modern hydraulic system used in operation and for maintenance alike. With this new type of roller suspension, the rollers can be swung out of the mill in a controlled way – for ease of replacing the onepart grinding roller .

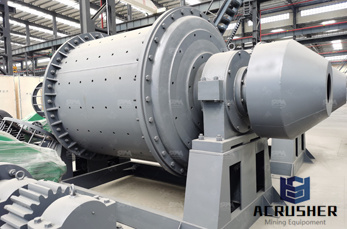

Feb 10, 2016· VRM vs Ball Mill for Cement Grinding. Good Days! Gentlemen, Anybody in this forum who have had some practical/extensive experience on Vertical Roller Mill being used for cement grinding? We are planning to put up a new cement grinding plant using Vertical Roller Mill.

vertical roller mill ube maintenance manual. what is the Max. Nitrogen gas pressure in accumulator for . May 12 2008 · Re what is the Max. Nitrogen gas pressure in accumulator for vertical roller millhydraulic cylinder ENGRs sir if we exceed or keep low this nitrogen pressure in accumulator then wat will hapend. we have loesche mill .

Therefore, ease of replacement and regeneration is a major feature of the mill. The MVR mill has a modern hydraulic system used in operation and for maintenance alike. With this new type of roller suspension, the rollers can be swung out of the mill in a controlled way – for ease of replacing the onepart grinding roller tires.

Oct 11, 2019· During the operation of the vertical roller mill, the contact surface is subjected to multiple crushing and grinding, which may result in damage to the overall quality of the vertical roller timely maintenance and protection of the vertical mill plays a key role in extending the life of the vertical mill.

Vertical roller mill Wikipedia. Vertical roller mill is a kind of grinding machine for cement, raw material, cement clinker, slag and coal slag. It has the features of simple structure and low cost of manufacture and use. Vertical roller mill has many different forms, .

The vertical roller mill (VRM) is firmly established in cement plants all over the world. The biggest issues facing plants are not due to the equipment itself, but more to do with how well mill maintenance is understood and how the mill is looked after following commissioning.

Roller Mill Maintenance Roller mills are used around the feed mill to perform a variety of tasks. Applications include crumbling pellets, cracking corn, dry rolling and steam flaking grain, and grinding corn, wheat, or milo for mash and pelleted feeds. While each application has some unique

At the beginning of 2020 Loesche received a followup order from Thanh Thang Group Cement JSC in Vietnam to supply two vertical roller mills. The two mills are destined for a new cement line at the .

Our vertical roller mill drives are standardized building block design as block assemblies. Simple constructions and highest reliabllity. 2. Saving Installation Cost . a. Because of compact size and light .

Then the maintenance of dry mill, vertical roller mill and other method of dry grinding equipment for what? The following is the detailed introduction of the related content. One, in the use of dry grinding equipment process, best to let the fixed operators time care, also require the operator to have certain operation ability and level ...

Maintenance of vertical roller mill; Maintenance of vertical roller mill. Author: guilin hong cheng Release date: 11:14:16. Equipment maintenance is essential to ensure equipment safety and efficient operation requiring particular stress laid. During operation, equipment may encounter abnormalities due to changes in the use of ...

Maintenance Details Of Vertical Roller Mill Summary. As the name implies, the presentation of vertical roller mills is more threedimensional, so the lateral footprint is smaller. Because the vertical roller mill .

LM fine vertical roller mill. New fine vertical roller mills is developed by our company, it create a particle size distribution with a sharper cut in comparison to cement milled in a traditional ball mill, the .

Loesche is an ownermanaged, exportoriented company, which was founded in Berlin in 1906. Today, the company operates from its head office in Düsseldorf and has subsidiaries, representatives and .

This is a medium speed vertical mill with conical grinding rolls per mill. The race will be either deep or shallow like saucer covered with liner called bullring segment. The bowl is rotated by a .

FOR VERTICAL ROLLER MILLS by Matthias Authenrieth, Thomas Hyttrek and Andreas Reintke, Loesche , Germany, and Steven McGarel, Senior Consultant, USA LMmaster_ 1 .

WhatsApp)

WhatsApp)