types of feeder for coal mill

Mill Steam Inerting System Review and ... Babcock Power. There are three (3) types of coal pulverizer systems1 designed for low, medium ... During mill shut down, the same inerting process starts when the coal feeder .

WhatsApp)

WhatsApp)

Mill Steam Inerting System Review and ... Babcock Power. There are three (3) types of coal pulverizer systems1 designed for low, medium ... During mill shut down, the same inerting process starts when the coal feeder .

inlet, and at the feeder discharge, to indicate the presence of coal on the feeder belt and to detect coal pluggage to the mill. Feeder Construction and Features Feeder Inlet The feeder inlet is constructed of solid, type 304, stainless steel. A replaceable stainless steel levelling bar shears the coal .

Depending on speed pulverizers are classified as lowspeed, mediumspeed, and highspeed mills. Pulverized coal burners may be located on the front or opposed walls or in the corners of the furnace. There are two types of fuelfiring systems: bin system and directfiring system. Coal feeders are either the volumetric or gravimetric type.

stamler usa feeder breaker crusher | Clinker Grinding Mill. stamler usa feeder breaker crusher. A full line of crushing equipment and grinding machine for use in processing quarried stone, rocks, aggregate, limestone, coal .

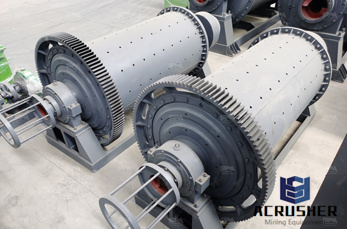

Types of Mill Feed Chute. Scoop Feeders for BallRod Mills are made in various radius sizes. Standard scoops are made of cast iron and for the 3′ size a 13″ or 19″ feeder is supplied, for the 4′ size a 30″ or 36″, for the 5′ a 36″ or 42″, and for the 6′ a 42″ or 48″ feeder.

A variety of mechanical feeders, including dragchain conveyors and rotary pocket feeders, historically have been used to volumetrically control the flow of fuel to coal pulverizers on power generators. Most power generation in the United States has relied on burning fossil fuels in steam boilers, with coal .

the combustors, with front and rear wall feed systems adapted to the distinct needs of this type of boiler. 3. Stoker Boilers are still in common use for single and multiple fuel applications. The Stock Batch Scale provides a precise flow of coal at exactly the usage rate and totalizes the quantity over time for accounting and economic purposes.

Bowl mills are used for pulverizing coal in pulverized coal fired boilers The coal to the mill is fed by a coal feeder from the coal bunker There are many type of feeders used for coal feeding like the belt feeder which can be in volumetric or gravimetric mode the chain link feeder the drag feeder etc Row coal from the yard is sized in crushers ...

End Mills are used for making shapes and holes in a workpiece during milling, profiling, contouring, slotting, counterboring, drilling and reaming applications. They are designed with cutting teeth on the face and edge of the body and can be used to cut a variety of materials in several directions.

The gravimetric feeder compensates for the variation in bulk density and feeds a fixed weight of coal in response to a boiler fuel demand. This ability to accurately weigh the coal provides significant improvement over volumetric types in terms of matching the fuel delivered by the feeder to the actual process energy required on coal fired units.

coal feeder types; Dry piston coal feeder This invention provides a solids feeder for feeding dry coal to a pressurized gasifier at elevated temperatures substantially without losing gas from the . . Besta Supplier, Besta mill feeder, besta coal feeder, .

The second role of the mill is to feed the required mass flow of coal to the furnace. .... developed specifically for a tube type mill which is significantly different to... Get Quote; Mill Feeder KH Systems. In order to cater to requirements of clients, we are offering Coal Mill Feeders to them.

Mill design features and benefits by Dr Caroline ... Gebr. Pfeiffer SE petcoke are processed. Two mill systems ... also find an application in grinding a wide variety of coal types in cement ... the mill such as rotary feeder or safety.

Dec 27, 2019· What are coal feeders? Coal Feeder is a device that regulates the amount of coal to be supplied into the Coal Mill. The amount of coal is regulated according to the needs in the boiler combustion chamber (furnace).. The number regulation system in the coal feeder can be done in two ways based on the type, namely by weight fraction or coal volume fraction.

stock coal feeders australia mactfc . types of coal feeder Crusher South Africa . stock coal feeder belt type for cfb. hard coking coal mines in australia; coal mine equipment in madisonville us; Stock Coal Feeders Australia, This page is provide professional coal petcoke mill rotary feeder types Products Feeders Gravimetric Pressurized Coal Feeders.

Nov 28, 2017· Coal transport from hopper.. it''s new generation feeder. Grandpa Amu creates a wooden arch bridge,no nails,very powerful craftsman Duration: 13:54. Grandpa Amu Recommended for you

Feeders for Williams Roller Millers. Since Williams Roller Mills are used on a wide range of materials, the proper feeder selection is essential for highcapacity, troublefree operation. You can customize your roller feed mill depending on what material you need reduced.

Pulverized coal boilers fire finely powdered coal, typically with an average particle size of about 25 µm ( in). Coal burns in suspension, like the combustion in an oil or gasfired boiler. Coal is pulverized in some type of large mill Pulverized coal is fired out into the furnace volume using burners that look somewhat like oil

For all Makes Models of Coal Feeders * Improve plant heat rate * Account for fuel use Volumetric operation of a coal feeder has served the industry for many years. In a volumetric system the flow of material is controlled by the boiler demand system, but the actual amount fed is estimated and the accuracy can vary greatly.

Pulverizers Coal Grinding Roller Mills William''s Vertical Roller Mill Pulverizers utilize centrifugal force to grind coal material while maintaining low operating costs. Featuring easily replaceable wear parts, automated process controls and infinite turndown thanks to VFAC drives, these machines are perfect to use as a coal mill.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

Jan 03, 2016· Engineering Animation Bowl Mill Dots 3D. Loading... Unsubscribe from Dots 3D? ... How Vertical Grinding Mills Work (Coal Pulverizer Example) Duration: 14:39. saVRee 3D 6,681 views.

Pulverized coal stationary blade feeders are designed for even feeding of pulverized coal from intermediate hopper to boiler burners. The feeder consists of the following major units: receiving hopper with lock, dozing machine, safety coupling, worm reduction .

Nov 17, 2012· pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. The coal flow is controlled by the feeder, allowing coal to flow into the pulverizer mill. The pulverized coal and air mixture is then transport to the boiler burner ...

WhatsApp)

WhatsApp)