ROSS 4" X 8" THREE ROLL MILL, FLOOR MODEL at Wohl Associates

1used ross 4" diameter x 8" long three roll mill, serial #33773. this floor mounted machine is driven by 1hp 3/60/230460 volt explosion proof motor.

WhatsApp)

WhatsApp)

1used ross 4" diameter x 8" long three roll mill, serial #33773. this floor mounted machine is driven by 1hp 3/60/230460 volt explosion proof motor.

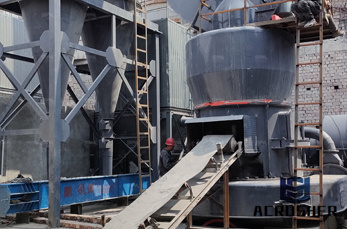

Three Roll Mills. The dispersion of medium to high viscous millbase can be achieved by our fully hydraulic Three roll mill. The shearing force created between the array of horizontally mounted counter rotating rolls helps in dispersion of the millbase like inks, industrial decorative paints, artists'' colours, chocolate, foodstuff, cosmetic products, etc.

A threeroll mill is used mostly for dispersion, but does some grinding as well. It uses three rollers of different speeds and directions to cause the sheer force between them to disperse and grind particles. The threeroll mill is used to disperse material within a media, which is usually some type of semiviscous material such as cream.

Oct 25, 2019· Find Used or Surplus Mills, Roll, Lehmann Ross Kent Keith Thropp AllisChalmers Directory of 70000 listings by 1200 suppliers

When Ross produced the first Three Roll Mill more than 80 years ago, we revolutionized pigment dispersion — with superior consistency and finer dispersion than ever before. Today the original Ross Three Roll Mills are still the standard by which all others are measured — in applications as diverse as magnetic coatings, cosmetics, paints ...

: Torrey Hills Technologies T50 Ointment Mill 2x7 Three Roll Mill Lab Model Mixer Ceramic Rollers Rolling Mill from Golden Bridge Award Gold Prize Winner Exakt/Ross Tradein Option: Industrial Scientific

Brought to you by THREE ROLL MILL 101; WHAT IS A THREE ROLL MILL A three roll mill has three horizontally positioned rollers. Each roller rotates in an opposite direction from the adjacent roller with a tiny gap between them, creating tremendous shear force that can finely disperse, mix, refine or homogenize viscous materials.

Charles Ross and Son Companyyfive years after introduced the Ross Three Roll Mill, it is said to remain the definitive roller mill for a wide variety of dispersion applications. Now, Ross offers a data sheet on its full line of Three Roll Mills for lab and production applications.

Used Ross 3 roll mill, carbon steel rolls approximately 12" X 30".

Jul 18, 2011· Arnold Equipment Company Test run of item #7313 described as follows: 1 used Ross in. dia. x 5 in. long Lab sized Ross Three Roll Mill. Model Ross Serial #100617.

charles ross son 3 roll explosion proof mill model 52c614 s/n 42891 new 1983 3 chrome cored horizontal rolls roll size 6" x 14" independant pressure adjustment stainless discharge shoot 5 hp 240 volt 2 speed great condition weight 1200 lbs mint condition

Manufacturer of Quality Products for Feed, Food and Industrial Applications : 120 Ton per Hour Steam Flaking System designed and erected by FerrellRoss Roll Manufacturing features three (3) FloMore® 96inch diameter X 53foot tall HighEfficiency StainlessSteel Steam Chests for optimal steam conditioning of grains prior to flaking with three (3) 32X68 Flaking Mills.

HOME PRODUCTS SERVICES DATASHEETS INDUSTRIAL MIXERS CHARLES ROSS AND SON COMPANY THREE ROLL MILL 52M 2 1/2" X 5" Charles Ross and Son Company List your products or services on Engineering360. Contact Information 710 .

Used Ross three roll mill, model 4X8TRM, 4" diameter x 8" roll faced width cored rolls, end guide holders less end guides, adjustable first and third rolls, knife apron discharge, approximately 1 hp motor with vfd controller, serial# 107948.

Used (Remanufactured) Three Roll Mills Keith Machinery Corp. (KMC) sells and services more three roll mills (TRMs) than everyone else in North America, combined. As of 01/01/16, KMC has more than 250 used TRMs in stock, ready for remanufacture.

Jul 23, 2015· Threeroll mills are available from this company in a wide selection of capacities and features that are reportedly suitable for handling any laboratory application. Shown here is the 5 x 12in. model with hardened carbon steel 52100 precision ground rolls, each cored for water cooling and heating. Standard handwheel controls reportedly feature a quick release/reset engagement mechanism for ...

Eweka Three Roll Mill 3 Roll Lab Mill #14880. Manufacturer: Eweka Three Roll Mill Three roll, table top, laboratory mill by ewekaapparatebau (germany), serial # ceramic 4" wide x 2" diameter roll s as part of modular device which mounts to drive unit along with other devices ...

is the most important platform for Three roll mill product online whole sales, most of the golden suppliers on the platform comes from Shanghai, Shandong, Jiangsu in China(Main Land), they produce qualified Three roll mill Three roll mill with certifications as iso9001:2008, ce iso or ce and support OEM and customized designs.

Products > Three Roll Mills > Three Roll Mill How the Three Roll Mill Works. The material to be milled is placed between the feed and center rolls. Each adjacent roll rotates at progressively higher speeds. For example; the feed roll may rotate at 30 rpm, the center roll at 90 rpm and the apron roll at 270 rpm.

1 – used Ross 4 in. x 8 in. Three Roll Lab Mill. Chrome plated steel rolls. With end guides take off knife and apron. Unitized on base with motor. Last used in the dental adhesive industry. Was in service at time of removal. – WEST COAST LOCATION

The most simple used (remanufactured) Three Roll Mill will have manual roll set, manual apron set, manual roll temperature control, quiet timing belt drive, and a TEFC inverter duty motor. Roll set options include manualhydraulic roll set, and electrohydraulic roll set.

Used Ross Bench Top Horizontal Three Roll Mill, Model X 5 (3) 430/40 Stainless steel 21/2" diameter x 5" wide cored rolls. Front roll speed 428 rpm, center roll 214 rpm, back roll 107 rpm.

One (1) used " x 5" Ross bench top three roll mill, model, " diameter x 5" long cored rolls, manually adjusted first and third rolls, on base with 1/2 HP 115/230 volt motor, serial# 59453.

Three Roll Mills. The material to be milled is placed between the feed and center rolls. Each adjacent roll rotates at progressively higher speeds. For example; the feed roll may rotate at 30 rpm, the center roll at 90 rpm and the apron roll at 270 rpm. Material is transferred from the center roll to the apron roll .

WhatsApp)

WhatsApp)