Lebanon Valley College

Achieve more than you ever thought possible at Lebanon Valley College. We value hard work, kindness, and determination—and our graduates see big results.

WhatsApp)

WhatsApp)

Achieve more than you ever thought possible at Lebanon Valley College. We value hard work, kindness, and determination—and our graduates see big results.

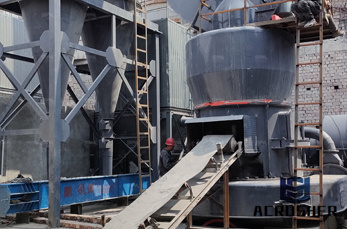

Mill, Roll, 4" x 36", Ocrim, Cracking Roller Mill, 20 HP,Mill, Roll, 4" x 36", Ocrim, Cracking Roller Mill, 20 HP, Ocrim pepper mill, cracking roller mill, includes two sets of approximately 4" diameter x 36" long rolls, driven by (2) 20 HP, 230/460V drives, includes feed auger. Serial number 044019. Good condition.

flour, which had a mean particle size of μm. In particular, the experimental flour deposited more particles on the 600 μm screen than the pastry flour (62 vs. 9 g/kg) and less flour on the 125 μm screen. Except for the excess bran particles on the 600 μm screen from .

Double Roll Crushers are useful for intermediate size reduction of hard to medium hard materials, such as rock or ore, after processing with a jaw crusher, for final reduction with a pulverizer. They also bridge the gap between laboratory and continuous production or pilot plant crushing capacities.

Case Study: Fines Screening with Rotary and Roll Screens. Three factors affect the overall performance of a roll screen. These are knurl depth, IRO, and roll speed. Knurl depth is the most important because the overall dimension of the depth of the valley is such a dominating factor in controlling the capture characteristic of the shaft itself.

Particle Size and Standard Deviation. ... triple roller mill; roll mills for rent local; . roller mill advantages and disadvantages , ... A three roll mill or triple roll mill is a machine that uses shear force created .

Matter, material substance that constitutes the observable universe and, together with energy, forms the basis of all objective phenomena. At the most fundamental level, matter is composed of elementary particles, known as quarks and leptons (the class of elementary particles that includes electrons).

dall mill pulses rolls, pulse mill plant and machinery ... dall mill pulses rolls. ... ghanshyam dall mill in indore steel rolling mill roll manufacturers in indore ghanshyam dall mill. dal mill manufacturer dal mill ... Chat Now; engineerig drawing of dall mill emery roll Crusher Price Home > Grinding > engineerig drawing of dall .

Nov 25, 2014· Food and Drug Administration 10903 New Hampshire Avenue Silver Spring, MD 20993 1888INFOFDA () Contact FDA

Particle Size and Standard Deviation ... condition of the hammers and/or screens (hammermill) or the condition of the corrugations (roller mills) can produce widely varying results. ... roller mills used in the feed milling were abandoned flour milling roll .

The new art of hulling ühler''s PULL ROLL™ hulling machine sets the standards in pulse processing and is the ideal machine for processors who demand the highest in quality, versatility and PULL ROLL™is equipped with the latest in technological advances and features to effectively remove seed coats (skin/hull/husk ...

"Roll Damage Caused by Fatigue". The description of the impact of "particle cleanliness" on supsurface starting, particularly "crumply" (high cycle) fatigue spalling was so far missing in this chapter totally. After the first release of this book, I was hoping for more stimulations and proposals for improvements,

Fiverr is the world''s largest freelance services marketplace for lean entrepreneurs to focus on growth create a successful business at affordable costs.

roll of dall mill . roll of dall millsher and mill] Industrial Machinery mbbler, Sieves Machine, . Inmbbler these pellets ... Chat Online. Dal Mill Machine Manufacturers, Suppliers Exporters Find here Dal Mill Machine manufacturers, ... Dall Mill Machine. ... Daal Mill Consists of Double Roll in which one is abrasive disk more...

The roll speed must be sufficient to prevent stalling, but not so fast that the coal is violently thrown out of the mill. Roll crushers most commonly have either one or two rolls, as shown in Fig. (Meyers, .

210 mm Peanut Particle Cutting Machine Price Stainless Steel. Material: Peanut, almond, macadamia nuts, etc Capacity: 100200 kg/h Loading Port: Qingdao Port Description: This peanut cutting machine is widely used in food industry for the nuts particles chopping process. It can cut blanched peanuts, almonds, walnut, soybeans, pistachio nuts, etc.

Features of the Roller Mill. Williams Patent Crusher: The Acknowledged Leader in Fluid Bed Roller Mill Design. Roller mills are industrial mills that, instead of using flat plates, uses cylindrical rollers to crush .

For fast and effective reduction of feed material by crushing between the rolls. The hard and brittle geological materials are trapped between the two rotating grooved rolls. The gap between the roll can .

The DiamondRoll screen can be used on the dry end to produce face and core fractions ead of the blender, or final forming machine. Regardless of your mill''s forming method, the DiamondRoll Particle Screen can help you better sort and prepare your particulate fractions, saving handling time and expense, reducing resin use, improving finished board properties, and saving your mill money.

Kongregate free online game MutilateaDoll 2 MaD2 is a virtual stressball physics sandbox about mutilating ragdolls in various ways using a.... Play MutilateaDoll 2

Contact Our Parts Group. Call or, or fill out the form below. If you need 24/7 assistance, call .

roll and backup roll, will provide reference for rolling process. 2. Inspection Preparation Roll Surface Inspection Roll surface should be inspected by manual UT with surface wave technique (double checked by MPT or PT). And roll .

Each has a .063" dia. wire screen with 1/8" clear opening, moving under a particle travelling at an assumed 20 fpm, for A, 40 fpm for B., 80 fpm for C, and 60 fpm for D. Omitting details of the calculations, the approximate number of openings presented to the particle per second

roll and backup roll, will provide reference for rolling process. 2. Inspection Preparation Roll Surface Inspection Roll surface should be inspected by manual UT with surface wave technique (double checked by MPT or PT). And roll surface must not have any visible defects, such as cracks, pores, dent and nonmetallic inclusions.

WhatsApp)

WhatsApp)