RollsForged RollsCold Mill Rolls

Rolls Forged Rolls Cold Mill Rolls from Metals America.

WhatsApp)

WhatsApp)

Rolls Forged Rolls Cold Mill Rolls from Metals America.

Selection of materials and roller roll surface hardness. Roll the choice of materials and work characteristics and damage roll form are closely related. Steel mill roll and have a larger impact force load, should have sufficient strength and hardness of the roll surface can be placed on second.

Finishing Roll Lifter for Cold Mill or Roll Grinding Facilities. This 90ton capacity finishing roll lifter handles mill rolls in a fully automated roll grinding cell in a steel mill. This unit is specifically designed for lifting clean or dirty rolls in and out of roll grinders and storage racks.

SOLVING Paper Roll Handlers for moving paper rolls into the machines, moving and handling paper rolls and reels between machine and storage and Roll Handling systems to transport large Mill Rolls from machine to slitter.

Calculator for Rolled Length of Roll of Material Calculates the rolled length of a roll of material when the outside diameter of the material, thickness of the material, and the diameter of the hole in the center or the tube on which the material is wound are given.

Clearance Fabric. We offer a wide range of clearance fabrics available from our online fabric shop. Our clearance fabrics include curtain fabrics and upholstery fabrics and are available by the metre or we also have a number of fabric roll ends.. We stock a number of fabric roll ends in our fabric warehouse that are ready to ship out to our customers on purchase.

Casting rolls is mill rolls supplier,exporter for TMT,Steel,Ferrous nonferrous roll mills ... like double pour in variety of metals and high performance alloys like Stainless steel / Aluminium and Bronze implementation of the rolls is specific to the industry types and usage and hence are manufactured with precision as per the ...

Roll Form Tooling Materials. Producers of tube, pipe and roll formed products are always looking for tooling materials that will give them the best results for the best cost. RollKraft has compiled a list of materials that are available today along with where these materials are best suited for use on your mills.

We offer Tube and Pipe mill rolls in a variety of materials.

Products > Three Roll Mills > Three Roll Mill How the Three Roll Mill Works. The material to be milled is placed between the feed and center rolls. Each adjacent roll rotates at progressively higher speeds. For example; the feed roll may rotate at 30 rpm, the center roll at 90 rpm and the apron roll at 270 rpm.

RollForming Guide for Building Panels Alignment Mill alignment is critical. Since tooling is designed to specific tolerances, the forming rolls and their components must be aligned to each other both horizontally and vertically. The rolls must be aligned both sidetoside and passtopass.

Sep 11, 2014· Cold rolled steel is essentially hot rolled steel that has had further processing. The steel is processed further in cold reduction mills, where the material is cooled (at room temperature) followed by annealing and/or tempers rolling. This process will produce steel with closer dimensional tolerances and a wider range of surface finishes.

Black EPDM Rubber Roofing Membrane, NR NonReinforced, UL ClassA Fire Rated, Clean (talc free), 60 mil, 10 x 50 Foot Roll. Price/Roll. (use Freight shipping; aka # 309655)

Materials Used In Roll Forming. Share: Roll forming is a process in which a strip or sheet of metal, such as steel, is passed through a continual set of stands (rolls) until the desired crosssection profile is achieved. The sheet or strip is plastically deformed along a linear axis in a room temperature environment. Typically used to create ...

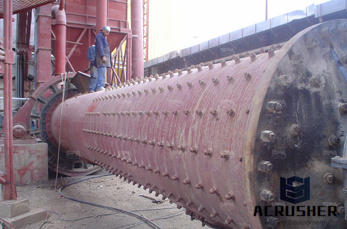

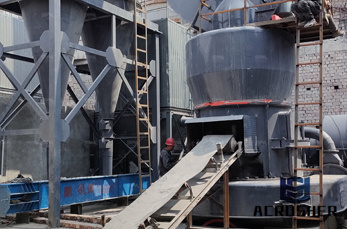

Mill Rolls. Kennametal manufactures mill rolls from cemented tungsten carbide grades tailored for the demanding environment of hot rolling mills that produce wire rod and seamless tube. We deliver mill rolls as unfinished blanks, semifinished rolls with ground inner diameter and .

Calculates the outside diameter of a roll of material when the rolled length of the material, thickness of the material, and diameter of the hole in the center or the tube on which the material is wound are given. ... An example of rolled material would be a rolled carpet or a rolled sheet of paper from the paper mill. The length units that can ...

Rolling Tools Composite Roll. Solid rolls are essential to the iron and steel industries. The heatresistant and deform resistant cemented carbide can mill steel heated to approximately 1000ºC. This contributes to the highefficiency rate in the production of steel. ... Mitsubishi Materials, the top supplier in the world of carbide rolls ...

WORLD CLASS ROLLS OF THE HIGHEST QUALITY FOR OVER 100 YEARS. The WHEMCO companies in Pennsylvania and Ohio, USA manufacture a full range of mill rolls – spun cast iron, cast steel and forged steel. Each of our roll manufacturing facilities has the expertise, equipment and experience to meet the most demanding rolling mill applications.

A major part of the raw materials of traditional roll covers has been manufactured from fossilbased materials, which has been refined and processed from crude oil. Valmet''s RD work focuses strongly on enhancing raw material and energy efficiency and promoting the use of renewable raw materials.

Vinyl Fabric by the Yard and Roll. Tarps Now has the largest selection of heavyduty Vinyl Fabric by the Yard and Roll that is waterproof; resistant to abrasion, tears, mildew, and UV rays; and meets military and fire department specifications.

Hot rolling is a metalworking process that occurs above the recrystallization temperature of the material. After the grains deform during processing, they recrystallize, which maintains an equiaxed microstructure and prevents the metal from work hardening. The starting material is usually large pieces of metal, like semifinished casting products, such as slabs, blooms, and billets.

Many hot strip steel mills around the world are realizing the benefits of the Xtek Bemcalloy™ Pinch inherent lubrication property of the graphitic constituent in the Bemcalloy™ material, along with the natural resistance to adhesion of dissimilar metals, is the basis of the pickup resistance of the material.

cold mill rolls, retooling and modernization of the production plant were carried out by the 1940. Since then, rolls for coldrolling mills have become an integral part of Uralmashplant''s assortment. Uralmashplant is rated among the leaders at the world''s roll market due to .

Roll Compression (Single roll and double roll Impact Hammer mill Double rotor Tertiary Single rotor . Asst. Prof. Dr. Ayşe KALEMTAŞ ... materials along tangential direction to impact plate at the other end of the crushing cavity. The materials are crushed again, and then, they return to

WhatsApp)

WhatsApp)