Coal Mill Puffs

Coal Mill Fineness Trouble. c e bowl mills coal Mill puffs or explosions can be very dangerous resulting in serious damage to the pulverizer system or.

WhatsApp)

WhatsApp)

Coal Mill Fineness Trouble. c e bowl mills coal Mill puffs or explosions can be very dangerous resulting in serious damage to the pulverizer system or.

The presence of combustible materials in the pulverizer is usually the largest contributor to pulverizer fires. In most cases, pulverizer fires begin in the under bowl area of the pulverizer that is a very hot environment with an abundance of air. Accumulations of debris or coal anywhere in the pulverizer will increase the chance of a mill fire.

Most of the explosions occurred during pulverizer shutdowns or restarts. The most common ignition scenario involved coal dust accumulations in the mill spontaneously igniting and coming in contact with a flammable coal dustair suspension during a mill shutdown or restart.

Review of Coal Pulverizer Fire and Explosion Incidents. Reports of 26 coal pulverizer fires and explosions are reviewed in order to elucidate causes and preventive measures. Most of the explosions occurred during ...

Review of Coal Pulverizer Fire and Explosion Incidents. Most of the explosions occurred during pulverizer shutdowns or restarts. The most common ignition scenario involved coal dust accumulations in the mill spontaneously igniting and coming in contact with a flammable coal dustair suspension during a mill shutdown or restart.

Feb 18, 2018· Coal is often the main fuel source used to heat the cement kiln. Coal pulverizers are required to grind the coal from the bulk storage size to a smaller particle diameter to use in the kiln. Coal pulverizers significantly reduce the mean particle size of the coal, drastically increasing the fire/explosion hazard risk.

Safety Content of CO in a Coal Bin [Archive] bulkonline Forums. Where are you getting carbon monoxide in a coal grinding plant? ... content is used for alert people if the coal is selfignition, in case explosion.

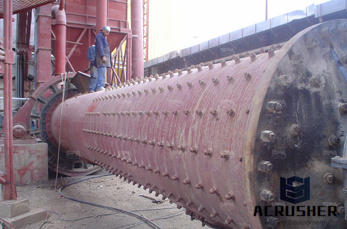

Pulverizers prepare raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion. In Part I of ...

Review of Coal Pulverizer Fire and Explosion Incidents ASTM ... ABSTRACT: Reports of 26 coal pulverizer fires and explosions are reviewed in ... paper is to review these coal pulverizer fire and explosion incident accounts.

Out of the 11 incidents with a reported loss of 1 Million and above, 8 were from fires and 3 were from explosions. Three incidents were recorded with losses above 15 million: Cotton Seed Elevator Fire in Altus, Okloma (20 Million) Coal Silo Explosion in San Juan, New Mexico (1520 Million) Metallurgic Dust Fire in Muskegon, Michigan (15 ...

Nov 01, 2018· Six of these incidents involved wood dust, sawdust, wood pellets and wood shavings. Five of these were fires and one was an explosion. This again demonstrates that both fire and explosion hazards need to be addressed in industries handling combustible dust. Additional information on specific incidents can be found at ...

Research on the Suppression of Coal Dust Explosions by Water 152 Barriers—ZHOU DIANBANG AND LU JIANZHANG Preventive and Design Measures for Protection Against Dust 158 Explosions—^WOLFGANG BARTKNECHT Review of Coal Pulverizer Fire and Explosion Incidents—ROBERT 191 G. ZALOSH

review of coal pulverizer fire and explosion incidents. review of coal pulverizer fire and explosion incidents; . south africa iron ore mining open casting jobs mates vibration control of ball mills. News . » .

procedures was a factor in all explosion • Many explosion incidents resulted when proper isolation, clearing, or shutdown procedures were not • Half of all explosions occurred during a hot • Hot furnace gases backing up into the pulverizer system was responsible for .

uses coal as the primary fuel. Conversion to coal was started in the 1970''s. In 1972, only 39 percent of the industry''s energy was supplied by coal. • Inland Cement, "We are also concerned about the potential fire and explosion hazard of working with coal and are confident that we can use coal safely.

In this instance a painter/insulator was working at the plant when a boiler explosion caused him to fall 6 to 8 feet. ... Coal pulverizer explosions occur frequently and in 1999 an explosion at a ...

The design "capacity" of the same pulverizer will grind 135,000 pounds per hour with fuel that is 55 HGI (Hardgrove Grindability Index) coal, ¾" raw coal top size, 7% moisture and produces pulverized coal that is 70% passing 200 mesh fineness (red line). This is pretty standard.

coal pulverizers power plants pulverizer/mill system One of the critical power plant components that is relied upon to convert the energy stored in coal into electricity is the coal pulverizer or mill. >> Chat Online; coal to electricity pulverizer .

Review of Coal Pulverizer Fire and Explosion Incidents ASTM . ABSTRACT: Reports of 26 coal pulverizer fires and explosions are reviewed in order to elucidate causes and preventive measures. Most of the explosions occurred during pulverizer shutdowns or restarts. The most common ignition scenario involved coal dust accumulations in the mill ...

Coal SiloBunker Firefighting Procedures . This article was written in the May, 2012 edition of Coal People magazine and reviews ... However, year after year we hear about a major fire or explosion in the coal industry. The reason these major incidents occur can often be traced back to a manageable

This page gives a summary of dust explosion incidents broken down by geometry including date, location, type of dust, and loss.

review of coal pulverizer fire and explosion incidents. D 3175, Standard Test Method for Volatile Matter in the Analysis Sample of Coal and Coke, for coal and coke dusts) ... mill fire, mill puff or a mill explosion.

WhatsApp)

WhatsApp)