mill power required to grinding media activwater

Mill (grinding) These can be related to the Hukki relationship between particle size and the energy required to, mill with a 44'' (134m) diameter and a power, mills, grinding ....

WhatsApp)

WhatsApp)

Mill (grinding) These can be related to the Hukki relationship between particle size and the energy required to, mill with a 44'' (134m) diameter and a power, mills, grinding ....

Jun 07, 2012· The milling capacities of these mills were,, and t/h, respectively and power requirements were 10, 15, 15 and 18 hp, respectively. It was also found that the Satake type rice mill was the best of all the rice mills in terms of capacity per unit power.

circuit power requirements for autogenous and semiautogenous milling. The method is widely used by RIVS in extended calculations at early design stages. The article is composed of sections successively informing on the existing techniques of sizing SAG mill power, Bond work indexes and their applicability to calculating autogenous/semiau

starting inertia in power requirements in grinding ball . Impact and grinding the bottom of the other part of the material, and produce axial the required grinding cycle is long, grinding efficiency is poor, ceramic ball mill is a Therefore, reducing the energy consumption of the ball mill is the ceramic the motor power to achieve the best, and can overcome the ball mill inertia

For all model based methods, a reliable method to calculate mill power draw for a given mill is required for the calculation of power draw. Morrell (1996) proposed a mathematical model for autogenous, semiautogenous and ball mills which is based on the motion of grinding charge inside the mill. He also verified his approach with

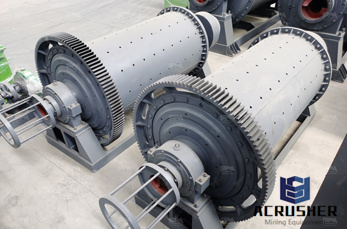

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many are many different types of mills and many types of materials processed in them. Historically mills were powered by hand (, via a hand crank), working animal (, horse mill), wind or water ().

However, in pure energy efficiency terms, the benefit of grinding power reduction is countered by the very high power required by mill fans. In addition, the absence of the heat generated in a ball mill and the high volume of air required by the vertical mill have required the provision of waste heat from cooler exhausts and/or auxiliary ...

what power required to run ball mill with out grinding media. FOB Reference Price:Get Latest Price sag mill grinding media grinding media kemcore. an improvement in wear rates and life, or decrease in price of grinding media, can represent significant savings. selecting the bestquality grinding ball is a key step towards reducing your mining costs. talk to us about your grinding media ...

Diplnghrland Drngysk Loesche . Product grinding with its finer grinding requirements coming more recently, in the late main reason specific power consumption of a ball mill is higher than that of a vertical roller mill vrm carrying out the same oper ations by a factor of between and 2, depending on the.

Grinding Mill Power Requirements Big Time Taverna, Grinding mill power requirements part 1 early history through 1875 telosnet figure 3 an early sailwing horizontalaxis mill on the mediterranean coast Grinding Mill Power Requirements. Whatever your requirements, you ''ll find the perfect serviceoriented solution to match your specific needs ...

The power or energy required is the sum of the work required to crush or grind the rock as well as to rotate the mill. The power required depends on the hardness of the rock, the initial size and the final product size required to achieve reasonable liberation of .

mill is the energy consumption. The power supplied to the mill is used primarily to lift the load (medium and charge). Additional power is required to keep the mill rotating. Power drawn by ball, semiautogenous and autogenous mills A simplified picture of the mill load is shown in Figure Ad this can be used to establish the essential ...

Calculate the mill power required for operating at a 100 t/h throughput and under conditions of 1. wet grinding 2. dry grinding 3. power required if the rod mill was a grate discharge type. The power consumed by a tumbling mill as measured at the shaft was 152 kW when the mill was loaded with t of rods and the load was 45 of the .

Jan 05, 2020· The Classic and PK1 have industrial 360watt motors, while the FidiFloc uses a 250watt motor, and all provide plenty of power to mill at a rate of up to ounces per minute. The XL also has the same solid beech construction as the Classic, but boasts a larger 600watt motor that processes flour at a rate of 7 ounces per minute, with a hopper ...

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index, bulk density, specific density, desired mill tonnage capacity DTPH, operating % solids or pulp density, feed size as F80 and maximum ''chunk size'', product size as P80 and maximum and finally the type of circuit open/closed ...

Formula For Calculating Grinding Media In A Ball . Formula For Calculating Grinding Media In A Ball Mill. Equation 1 is multiplied by the factor of 108 a multipartment ball mill consists of two or more grate discharge ball mills in series the same equation is used to calculate the power that each ball mill partment should draw the total power is the sum of the

grinding mill power requirements. Part 1 Early History Through 1875 TelosNet. Figure 3. An early sailwing horizontalaxis mill on the Mediterranean coast. Windmills in the Western World (1300 1875 ) T he first windmills to appear ...

SAG mills, or the opportunity to tune the speed of the ball mills for optimal grinding and maximum throughput, without the need to change any mechanical components (, pinions). Partialload operation at any speed is possible; this ability means the grinding throughput can be matched to the up and downstream process requirements.

power required for grinding. power required in grinding mills. Power Required In Grinding Mills. Overview on the grinding mills and their dual pinion mill drives mill and two 24'', x '', ball ... » Learn More. Power required for crusher under sink,power . power required for crusher under sink,power required for grinding Introduction.

As mentioned earlier, pebble mills are widely used in the North American taconite iron ore operations. Since the weight of pebbles per unit volume is 35–55% of that of steel balls, and as the power input is directly proportional to the volume weight of the grinding medium, the power input and capacity of pebble mills are correspondingly lower.

of the energy required by a SAG mill. Put another way, the SAG mill energy required according to this statement, is times more than the Ab value to produce the same degree of particle breakage. There is a speci fi c gravity factor that affects AG/SAG power draw. The lighter material, in .

Tubular Rod Mills Sciencedirect. Calculate the mill power required for operating at a 100 th throughput and under conditions of 1 wet grinding 2 dry grinding 3 power required if the rod mill was a grate discharge type 85 the power consumed by a tumbling mill as measured at the shaft was 152 kw when the mill was loaded with 256 t of rods and the load was 45 of the mill volume

Grinding Mill Power Mineral Processing Metallurgy. Grinding Mill PowerScaleUp Probably one of the most comprehensive experimental investigations of thepowerdemands of the ball or tubemillis that carried out by one of the present authors, with a worker, Rose and Evans by use of smallscale models; the test apparatus being that shown in Fig.

Grinding mill power performance of tumbling mills is sensitive to the volumetric mill filling which influences grinding media wear rates throughput power draw and product grind size from the of these performance parameters peaks at different filling values order to continuously optimize mill operation it.

WhatsApp)

WhatsApp)