Behind the Scenes: TimkenSteel Piercing Mill YouTube

Jan 08, 2015· Seamless tubing veteran Steve Agger takes you on a walk through the piercing mill for a quick look behind the scenes.

WhatsApp)

WhatsApp)

Jan 08, 2015· Seamless tubing veteran Steve Agger takes you on a walk through the piercing mill for a quick look behind the scenes.

Aug 16, 2001· Tube mill operators face a variety of challenges every day in their effort to produce highquality tubing in a costeffective and productive way. This article examines some of the typical problems producers encounter, some common causes of these problems, and some ideas for how to solve these ...

Jul 26, 2017· Rod Mill in Operation Fuad Sillem. Loading... Unsubscribe from Fuad Sillem? ... HOME BUILT (BALL MILL)BERDAN PAN fine Gold Extraction FIRST LIVE RUN Duration: 5:41.

Some of the earliest literature on rolling mills can be traced back to Christopher Polhem in 1761 in Patista Testamente, where he mentions rolling mills for both plate and bar iron. He also explains how rolling mills can save on time and labor because a rolling mill .

from the Nations1 Tube Research Leborntory conducted a p'' roll. soyarating force test with the in place. 1, test the top roll was removed and decontaminated of u:c two sets of rdls, after futile attempts to remove tl :ii so?.vcnt end scraping, were sent to the machine shop 0D.

LM Home > LM Sites > Considered Sites > U S Steel Co National Tube Div Christy Park Works PA 35. FUSRAP Considered Sites. ... Metal fabrication operations. Pierced normal uranium billets by the three roll Assel Mill process. ...

Careers / Rolling Machine Setters, Operators, and Tenders, Metal and Plastic Summary Description Set up, operate, or tend machines to roll steel or plastic forming bends, beads, knurls, rolls, or plate or to flatten, temper, or reduce gauge of material.

Jan 22, 2014· Each product is manufactured in accordance with customer specifications, including heat treatment for more demanding applications. Our pipes are .

Products. Service. Knowhow. Instructions for Usage Maintenance Safety ROLLING MILL SAFETY, CARE AND TIPS 1. ALWAYS bolt down your rolling mill to a secure bench or secure stand for stability and safety. 2. Ensure guards are in place at ALL times. The guards are the black plastic covers, covering the gears. 3.

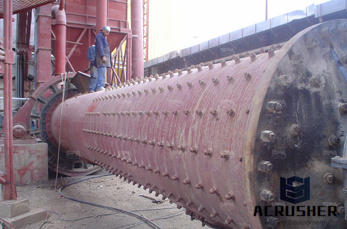

Rotary piercing is a hot working metalworking process for forming thickwalled seamless tubing. There are two types: the Mannesmann process and the Stiefel process. ... The formed tube is then cooled and can be cold worked to refine the diameters and to achieve the desired yield strengths. Mannesmann mills can produce tubes as large as 300 mm ...

The distinctive features of JFE Steel''s pipe and tube manufacturing technologies are outlined in the following. Seamless Pipes and Tubes JFE Steel has two seamless pipe manufacturing lines at Chita Works, the smalldiameter seamless pipe mill using the Mannesmann piercing/mandrel mill process and the mediumdiameter seamless pipe mill using

Jul 01, 2013· Threeroll mill how to dump operation, a detailed demonstration If you want to know more please log on to our website

The maximum possible draft in a rolling operation depends on which of the following parameters (two correct answers): (a) coefficient of friction between roll and work, (b) roll diameter, (c) roll velocity, (d) stock thickness, (e) strain, and (f) strength coefficient of the work metal?

Tube Mill Roll Sets Manufacture In medabad Crusher USA... product specification we are engaged in steel tube mill roll set. we have an expert team of manufacturer ... » piercing operations interfaced with a tube roll ...

The Hot Rolling Process The primary function of the Hot Strip Mill is to reheat semifinished steel slabs of steel nearly to their melting point, then roll them thinner and longer through 12 successive rolling mill stands driven by motors totaling 77,000 hp, and finally coiling up the lengthened steel sheet for transport to the next process.

a pair of skew rolls, the piercing mill presses the billet against a plug to pierce the billet, and then rolls the billet between rolls and the plug, forming it into a hollow tube of the prescribed outside diameter and wall thickness. During this Mannesmann process, the hollow tube is elongated by a mandrel mill, a plug mill.

is unquestionably the best resource on the Internet for career and college information. Their long list of free services includes career profiles, career videos, salary data, college profiles, information on majors and degrees, financial aid advice, and career assessment tests.

Rotary Tube Piercing Rotary tube piercing, also called roll piercing, or the mannesmann process, is a hot forming process that can manufacture long lengths of seamless tube and pipe. Compressive forces applied to a cylinder will create internal stresses at the center. These stresses result in crack propagation.

The tube is rolled passing through each stand while the cylindrical mandrel moves at a constant controlled speed during the whole rolling phase. At the end of FQM rolling, the mandrel returns rapidly through the mill back in the starting position, while the tube is extracted from the mandrel by means of a extracting mill located inline with ...

A tuberolling mill using shortmandrel draw equipment includes a piercing mill. Two piercing mills are used to roll pipe with a diameter exceeding 200–300 mm; the second piercing mill is used to decrease the pipe wall thickness and increase the diameter of the shell. The shortmandrel, or automatic, draw mill is installed after the piercing ...

As an example, a cold drawn tube may have to be drawn 34 times to equal the same amount of work of a pilger mill. Each time a tube is cold drawn, the tube must be cleaned and annealed (softened) before drawing again. For producing very small quantities of tube alloys, cold drawing has the advantage with quick tool changes and low operational ...

In the Mandrel Mill Process, a solid round (billet) is used. It is heated in a rotary hearth heating furnace and then pierced by a piercer. The pierced billet or hollow shell is rolled by a mandrel mill to reduce the outside diameter and wall thickness which forms a multiple length mother tube.

Long products Casting, rolling, tube, pipes, extrusion, forging and finishing lines. 3/6. RESET. Bloom Casters. Billet casters. Beam blank casters. Inspection and Conditioning Lines Billet and Bloom Grinders. Reheating Furnaces for Long ... H³ Wire Rod and Barincoil Mills Drawing Plants. Peeling Machines ...

In this article you will learn about metal rolling and drawing and the difference between these two deformation processess. Read for more details ... Care of the rolling mill. Do not roll any hard and brittle materials like steel or oxidized metal. ... Making a Tube.

WhatsApp)

WhatsApp)