Cement Plants located in United States The Global Cement ...

Cement plant locations and information on United States can be found below. For full access to the database, purchase The Global Cement Report™, 12th Edition ...

WhatsApp)

WhatsApp)

Cement plant locations and information on United States can be found below. For full access to the database, purchase The Global Cement Report™, 12th Edition ...

This is the 3D Auto cad drawing. This is the second department in the Cement Plant. All related unit foundation drawings are made available in the 3DFoundation Erection drawing.

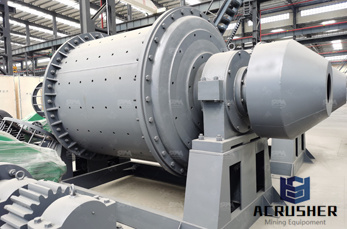

Volume 3, Issue 5, November 2013 388 hotair furnace may be used to supply this heat, but usually hot waste gases from the kiln are used. For this reason, the raw mill is usually placed close to the kiln preheater. Ball mill is used in cement industry. After the dry chamber material enters the 1st grinding chamber. 1st grinding chamber:

Raw Mill Is Widely Used In Cement Plant. Raw mill is the key equipment for secondary grinding after crushing. And it is suitable for grinding all kinds of ores and other materials, no matter wet grinding or dry grinding. Raw mill is mainly used in grinding raw materials and end products in cement plant. It is also suitable for various ores and ...

Aug 26, 2016· how ball mill works internaly, worldcrushers how raw mill work in cement plant, cement mill, ball mill, iron ore shibang china com; how to make a hammer mill; internal grinding machine ...

Cement kilns are used for the pyroprocessing stage of manufacture of Portland and other types of hydraulic cement, in which calcium carbonate reacts with silicabearing minerals to form a mixture of calcium a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant.

A mio t/a cement plant is having a closed circuit ball mill for cement grinding: The mill has been operating with satisfactory performance interms of system availability and output, however power consumption was on higher side. System Description Mill Rated capacity 150 t/h OPC at .

Aug 30, 2012· Raw materials are extracted from the quarry and by means of conveyor belt material is transported to the cement plant. There are also various other raw materials used for cement manufacturing. For example shale, fly ash, mill scale and bauxite. These raw materials are directly brought from other sources because of small requirements.

Raw mill and separation, The clinker cooler exhaust fan plays a critical role in the cement making process Raw mix enters the kiln and, ABB drives in cement | 11. Cement Plant Raw Mill Penta Engineering Corporation. PENTA Engineering Corp completed a cement plant raw mill and kiln conversion project at Hagerstown for Lafarlcim. process ...

Do your know how does the raw mill work in the cement plant? This paper mainly introduces the raw mill in cement plant. In order to achieve the desired setting qualities in the finished product, a quantity (28%, but typically 5%) of calcium sulfate (usually gypsum or anhydrite) is added to the clinker and the mixture is finely ground to form ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Vertical roller mill is a kind of grinding machine for cement raw material, cement clinker, slag and coal slag. It has the features of simple structure, low cost of manufacture and use. Vertical roller mill has many different forms, but it works basically the same.

Optimisation Shree Cement Plant. Shree cement plant optimization Beawar Rajasthan ... measure gas flows in the cement making process namely Raw Mill and Coal Mill gas flow, TAD, ... The four main fans only have a capacity of almost 6000 kW which is a major share of the ... process which requires several weeks and for ongoing operation in the ...

how a raw mill in cement plants works; raw grinding mill for cement; vertcal mill by fls for raw mill yemen; cement raw mill operator in qatar; raw material cement factories in pakistan; quotation format raw stone suppliers; torque speed characteristics of vertical raw mill; limestone vertical raw mill; fineness x power motor vertical raw mill

flow daigram of raw mill in cement plant lebhv. Plant design (capacity, design of equipment for raw material crushing, milling, clinker production and cement milling, plant layout and flow sheets) Calculation of mix (SM/LSF, Alumina Ratio), Alkalis and bypass engineering

Rawmill Wikipedia, the free encyclopedia. A medium sized dry process roller mill .... However, cement raw materials are for the most part dug from the Earth''s crust and contain most of the ... 1970 the situation has changed dramatically, and new wet process plant is now rarely installed.

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

Raw Mix Preparation Raw Mix Optimization Raw Mill Optimization ... on modules work in concert to help the cement plants to achieve their desired quality, cost and safety targets. Online ... material proportions in the raw mill feed. As in the former module, Model Based Control techno

Our bestinclass OK™ Mill is a globally successful vertical roller mill solution for grinding raw material, cement and slag. Its cuttingedge design features consistently deliver the highest quality products with the greatest efficiency. It is affordable to install and cost effective to operate over your cement plant.

Summary: The main trends concerning grinding processes in the cement industry are still higher efficiency, reduction of the power consumption and system simplicity. In the case of new orders, vertical mills have increased their share to over 60 % and ball mills have fallen to less than 30 %.

how raw mill work in cement plant BINQ Mining. ... working of vertical raw mill in cement plant 15 Oct 2013 working of raw mill in cement plant in pdf format SMMI Machineworking of raw mill in cement plant ... >>TYY LXP. raw mill in cement plant Gold Ore Crusher.

Dec 01, 2017· In one example mill, we consider the fineness and the energy consumed for eleven months for a cement mill. In the first five months, we found that this plant has been producing cement quality more than what is necessary to produce. As a result, this plant is consuming at an average 15% more energy than what is necessary.

Cement Raw Mill cement vertical raw mill is also called raw meal vertical roller mill, and it is the core equipment applied for cement raw meal grinding. cement vertical raw mill fineness of final product can be adjusted between 80 and 425 meshes and part of then can add up to 1000 meshes of final being equipped particular parts ...

Clinker is the raw material used to manufacturing the cement. The clinker plant comprises of feed pre crusher, feed hopper, table feeders, ball mill, packaging cement plant and material handling equipment. However, the operation of the plant consists of basically four processes viz. quarry, raw mill grinding, coal grinding and kilnburning. ...

WhatsApp)

WhatsApp)