gearless mill drive Mining Magazine

Mining Magazine Latest mining and investment news. ABB continues drive contract for Cerro Verde six years on. In the March quarter of 2012, ABB was contracted to supply gearless mill .

WhatsApp)

WhatsApp)

Mining Magazine Latest mining and investment news. ABB continues drive contract for Cerro Verde six years on. In the March quarter of 2012, ABB was contracted to supply gearless mill .

TECHNICAL AND COMMERCIAL BENEFITS OF GEARLESS MILL DRIVES FOR GRINDING APPLICATIONS M. rens, ABB, Switzerland J. Gonser, ABB, Switzerland ... The first Gearless Mill Drive (GMD) with a power of MW was ... Comparison of Drives Systems for Grinding Applications

Direct drive technology has been praised for its design, which is less complex than gearbox technology, leading to easier operations and maintenance. This appeal has made direct drive especially ...

Presently the gearless drive is more costly than the complete mechanical portion (mill rotating element and accessories supplied by the mill manufacturers) and hence the customer/consultant needs to have two parties to deal with from the start of any project. There is an interface between the mill vendor and the gearless motor supplier.

ABB recently won an order worth 44 million US to deliver three gearless mill drive systems (GMDs) for a new copper mine to be operated by Kazakhmys PLC (Kazakhmys) in southeastern Kazakhstan. The contract was awarded in the first quarter of 2012. Kazakhmys is the largest copper producer in Kazakhstan and one of the top copper producers in the ...

DESIGN REVIEW OF GEARLESS MILL DRIVE: MILL SYSTEM ANALYSIS Thulare Bopape, Hennie Klopper Anglo Technical Solutions Abstract: It has been well established that a critical component of the upfront design for large mills is a full system Finite Element Analysis (FEA), including the mill and its bearings, the motor, the foundation and the soil.

In ore processing, grinding is an essential step for the overall performance of any mine. That is why the gearless drive of a grinding mill is one of the most crucial pieces of equipment in the concentrator and why it is subject to particularly high demands. Siemens has provided about 80 SIMINE Gearless mill drives to the mining industry since ...

Gearless mill drive systems for copper mine in Zambia Sentinel copper mine, Zambia ... high efficiency mills are top priority. Siemens Gearless Mill Drives result in reduced total costs and assure a high performance, in accordance with the production requirements of a mining operation. Decrease text size Increase text size Text Size Print;

Our GMD eliminates all mechanical components of a conventional mill drive system, such as ringgear, pinion, gearbox, coupling, motor shaft and motor bearings: By mounting the rotor poles directly onto the mill, the mill itself becomes the rotor of the gearless motor.

Oct 15, 2012· A detailed animation showing the workings of a Gearless Mill Drive (GMD), created from a series of CAD files and insitu photographs.

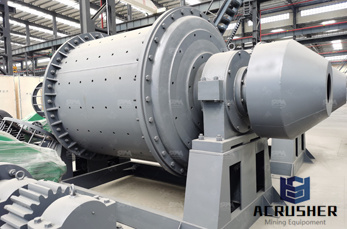

Gearless mill drive images To download this file, rightclick on the icon and select, "Save target as..." Icon image: File (jpg format) File size: Picture caption: _: 10723 kB: Two GMD systems for 27foot ball mills at Esperanza copper mine, Chile: _: 8605 kB: GMD system for a 40foot semiautogenous (SAG ...

plied gearless drives for two 36foot ring motors, developing a 12,000 kW gearless drive for the Kennecott, Ut, SAG mill and a 11,200 kW gearless drive for the El Teniente, Chile, SAG mill. In a continued call for larger, even more powerful drives, Siemens kept pace. In 1996, Freeport ordered the first gearless

The gearless drive system includes four lowspeed synchronous motors ( MW, 66 rpm) and the associated SINAMICS SL150 converters. ... The gearless mill drives operate more energy efficiently, having a 5% higher efficiency factor than conventional drive systems.

Gearless mill drive images To download this file, rightclick on the icon and select, "Save target as..." Icon image: File (jpg format) File size: Picture caption: _: 10723 kB: Two GMD systems for 27foot ball mills at Esperanza copper mine, Chile: _: 8605 kB: GMD system for a 40foot semiautogenous (SAG ...

4 days ago· Two 28 MW gearless mill drive systems (GMDs) are operating in the company''s 40 ft SAG mills and four MW GMDS are employed in 26 football mills along with associated control systems. "Gearless mill drives are the ''workhorses'' for .

ABBs Gearless mill drive system is the most powerful mill drive system in the market to power semiautogenous SAG ball and autogenous AG mills Advantages of Gearless Motor Drives in Large Ore Mining and Ore processing plants use mills with very high capacity drives Gearless motor drives are the alternative to the conventional motor . Live Chat

Gearless Mill Drive Motor Specialist. Siemens Belmont, WA, US. Apply on company website. Gearless Mill Drive Motor Specialist Siemens Belmont, WA, US 4 days ago Be among the first 25 applicants.

• 28 MW GMD for 42'' SAG mill Whether it is size or an installation at the highest altitude (4600 ), ABB''s GMDs are well positioned to contribute to the building of larger and ever more powerful mills. — Leading the gearless mill drive evolution The ABB gearless mill drive (GMD) is the most powerful mill drive system available,

Gearless Mill Drive Protection Improvements and Its Behaviour at Abstract—A cycloconverterfed gearless Chat Online. gearless mill drive comparison Get Details; SIMINE Gearless Mill Drives When the SIMINE Gearless mill drive is in inching mode, one rotation of the mill is all you need.

Nov 08, 2016· ABB Motor Gearless Mill Drive GMD System. Top 7 Mistakes Newbies Make Going Solar Avoid These For Effective Power Harvesting From The Sun Duration: 7:14. LDSreliance 2,588,365 views

3 days ago· In all, two 28megawatt gearless mill drive systems (GMDs) are in use at the mine''s 40ft SAG mills, and four GMDs are employed in 26 football mills. "Gearless mill drives are the ''workhorses'' for grinding operations, which are at the heart of any mine," ABB''s Cobre Panama project manager Rene Chacon said.

The comparison of a conventional drive train to a gearless drive for a grinding mill is shown in figure 1. Figure 1 – Top view of SAG mills with alternative drive options; left side: dual pinion drive including motor, gearbox, pinion and girth gear; ... The Gearless Mill Drive system consists of the ring motor with its feeding cycloconverter ...

Gearless (direct drive) hub motors. ... How do geared and gearless hub motors compare? Direct drive hub motors are capable of providing large amounts of torque and power. This makes them especially well suited for higher performance ebikes. Direct drive motors are usually big and heavy which adds to overall bike weight and decreases range.

Gearless mill drives (GMDs) have been installed on platinumminer Anglo Platinum''s Potgietersrust Platinum (PPRust) 600 000 t/m concentrator.

WhatsApp)

WhatsApp)