coal processing primary sizing

Elko Coking Coal Project Pacific American Coal Limited. A process flow diagram has been established to identify major capital components ... Primary sizing station, Secondary sizing station, including rolls .

WhatsApp)

WhatsApp)

Elko Coking Coal Project Pacific American Coal Limited. A process flow diagram has been established to identify major capital components ... Primary sizing station, Secondary sizing station, including rolls .

coal processing primary sizing. ... Nov 17, 2015Large surface coal mines rely on primary crushers to provide a consistent product. Unlike their bituminous counterparts that screen and wash coal, the mines extracting subbituminous coal and lignite are only looking to reduce the size of Run of Mine (RoM) coal.

A crude oil refinery is a group of industrial facilities that turns crude oil and other inputs into finished petroleum products. A refinery''s capacity refers to the maximum amount of crude oil designed to flow into the distillation unit of a refinery, also known as the crude unit.. The diagram above presents a stylized version of the distillation process.

Dump trucks haul the rock to the primary crushers in the open pit or to the ore stockpiles from underground. See more detail on mining. 2. Crushing The primary crushers located at the open pit mine site, receive ore and waste at separate times. They break the larger rocks down to a size suitable for transport on the conveyor belt.

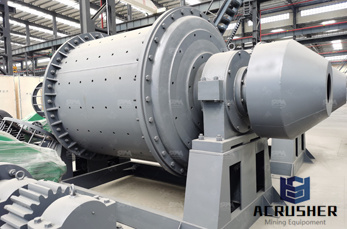

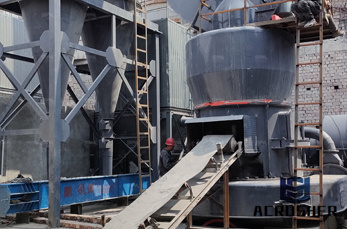

Primary, secondary and tertiary ore sizers. MMD''s continuous development and innovation culture has led to extensive development of its sizer design, offering a range of primary, secondary and tertiary sizing machines, with the largest capable of processing more than 10,000t/hr.

There are four main coal types: lignite, subbituminous, bituminous and anthracite. Here''s a look at their characteristics and uses. Found in the earth''s crust, coal is a fossil fuel that is ...

What are the Uses of Coal? Electricity production is the primary use of coal in the United States. Most of the coal mined in the United States is transported to a power plant, crushed to a very small particle size, and burned. Heat from the burning coal is used to produce steam, which turns a .

Mineral Processing Wastes Covered by the Mining Waste Exclusion. Slag from primary copper processing. Slag from primary lead processing. Red and brown muds from bauxite refining. Phosphogypsum from phosphoric acid production. Slag from elemental phosphorous production. Gasifier ash from coal gasification. Process wastewater from coal gasification

Print is not supported on Firefox. Please click ''OK'' to first download this report and then you will be able to open print the downloaded pdf.

Coal is used in cement manufacturing, food processing, paper manufacturing and alumina refineries. Black coal was first discovered in Newcastle 1791 and coal mining and exports commenced soon after in 1799. These early coal mining activities made a significant contribution to the progress of European settlement in Australia.

449 Int. J. Mech. Eng. Rob. Res. 2013 Girja Lodhi, 2013 OPERATION AND MAINTENANCE OF CRUSHER HOUSE FOR COAL HANDLING IN THERMAL POWER PLANT Girja Lodhi1* *Corresponding Author: Girja Lodhi, Many utility systems in the world have power plants operating with fossil fuel.

Do You Know a coal miner who would like to become a WV State Mine Inspector or Safety Instructor? Go to this page for more information. The West ia Office of Miners'' Health, Safety and Training is responsible for the enforcement of the West ia Mine .

Coal and Carbon Emissions Burning coal releases gases and particulates that are harmful to the environment. Carbon dioxide is the primary emission. Carbon dioxide is an essential part of our planet''s atmosphere. It is called a greenhouse gas because it absorbs and retains heat in the atmosphere, and keeps our planet at a livable temperature.

The MMD group of companies is a world leading specialist in the processing and reducing of natural and manufactured minerals using Sizer technology

Sizing affects the way the paper will react with various inks. Without any sizing at all, a paper will be too absorbent for most uses except as a desk blotter. A sizing such as starch makes the paper resistant to waterbased ink (inks actually sit on top of a sheet of paper, rather than sinking in).

coal processing primary sizing Coal Processing Primary Sizing . coal processing primary sizing coal processing primary sizing coal russian, Coal Anthracite, Bituminous, Coke, Pictures, Formation, answer to that question is the primary reason that the formation of a coal seam size, and crushing ...

outside the mining area for placement and storage. In the Midwest, where the surface topography and coal seams are generally flat, it is common to employ area strip mining in which the fragmented overburden is placed directly by large draglines in the space created where coal has been mined ().In some situations in the eastern United States, a coal seam occurring near the top of mountains is ...

Primary air to secondary air ratios ; ... Coal Analysis for Boiler Designers – Hydrocarbon fuels are the major source of energy for power and process steam generation, and coal takes a major share in this. Boiler furnace design will depend more on fuel characteristics, and further heat transfer surface sizing will depend on furnace outlet ...

United States EPA600/785024 Environmental Protection June 1985 Research and Development COAL SAMPLING AND ANALYSIS: METHODS AND MODELS Prepared for Office of Air Quality Planning and Standards Prepared by Air and Energy Engineering Research Laboratory Research Triangle Park NC .

Because the primary risks of coal use are environmental rather than economic or securityrelated, technology development and deployment that reduce environmental impact are critical to sustaining coal''s contribution to energy needs. (Sustainable Energy Strategy, 1995)

Heated (primary) air is supplied in the lower portion of the pulverizer to provide some coal drying and to transport the pulverized coal to the downstream combustion process. The coal ...

Mechanical screening, often just called screening, is the practice of taking granulated ore material and separating it into multiple grades by particle size. This practice occurs in a variety of industries such as mining and mineral processing, agriculture, pharmaceutical, food, plastics, and recycling.

Coal trade. Coal is traded all over the world, with coal shipped huge distances by sea to reach markets. Overall international trade in coal reached Mt in 2016; while this is a significant amount of coal it accounts for about 18% of total coal consumed. Most coal is used in the country in which it is produced.

Mar 22, 2010· FireRescue magazine''s Fireground Operations column COAL WAS WEALTH: The basics of sizeup, part 2 By Freddie LaFemina Editor''s Note: For the complete 13point sizeup strategy, be sure to read part 1 of this article. Last month, I addressed the first seven points of a 13point sizeup strategy (COAL WAS WEALTH) for evaluating problems encountered during firefighting operations.

WhatsApp)

WhatsApp)