Pulverizers 101: Part I

Pulverizers prepare raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion. In Part I of ...

WhatsApp)

WhatsApp)

Pulverizers prepare raw fuel by grinding it to a desired fineness and mixing it with the just the right amount of air before sending the mixture to boiler burners for combustion. In Part I of ...

There are many types of mills and bowl mill is one of them, all these mills can face coal hangup. For taking corrective action during a coal hangup in bowl mills the operator will have to know the reason for such a hangup, how the plant will respond, what he has to respond to and what the local operator will have to do. This will reduce the chance of mill trip and bring back boiler to ...

How much does it cost to generate electricity with different types of power plants? The Energy Information Administration (EIA) has historical data on the average annual operation, maintenance, and fuel costs for existing power plants by major fuel or energy source types in Table power plant operating expenses for major investorowned electric utilities 1 of the Electric ...

Combustion Engineering 783RP BowlMill Coal Pulverizer. enclosed chamber with wear resistant plates. The hammers impact on the coal, crushing it ... operation and maintenance. In practice, this has often been found not to be true. ... the power plant installed one assembly on each of the 30 pulverizers in its facility. The plant currently

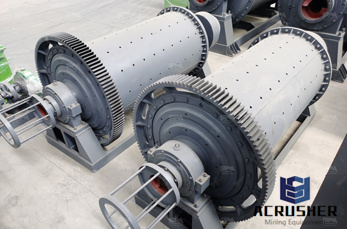

Coal Fired Power Plant Case Study: Coal Crusher Gearbox Lube Filtration Total System Cleanliness Approach ISO 9000 Certified . The Problem Coal fired power plants typically operate several ball mills or coal pulverizing mills to crush the incoming coal to the optimum size for combustion. This means that each

crushing coal grinding mill operation power plant . Jun 13, 2014 ... Coal grinding process is the process of coal was broken and its surface area Bowl Mills major auxiliaries in a coal fired thermal power .

Sep 07, 2016· This video is unavailable. Watch Queue Queue. Watch Queue Queue

mode of operation. All of these factors would tend to have a negative impact on a unit''s thermal efficiency. 1. Optimize Power Plant Operations Primary Air Secondary Air Coal Coal Handling Mills Ash Ash Air Heater ESP ID Fans Steam Turbine ~ LP Feedwater Heaters HP Feedwater Heaters Coal quality and variability effects on boiler efficiency,

design power plant operations, startup, costs, cost analysis, testing, life assessment, chemistry, maintenance and reliability. 16 poWer plAnt oM and Asset optiMizAtion Figure 1: Cumulative tube leaks versus unit starts for a 600 MW coalfired unit Philip M. Besuner is a reliability engineer. He as a MS in mechanical engineering with special ...

Jun 30, 2014· The retirement of coal plants could actually provide further opportunities for CHP at paper and pulp mills however, Scharff and Petersen noted. They envision utilities launching new power plants, potentially biomass or gas plants, located next to mills that could turn the resulting heat into thermal and extra electric power.

May 04, 2011· Y. Yan, in Advanced Power Plant Materials, Design and Technology, 2010. Introduction. Coalfired power stations are burning an increasingly varied range of fuels and fuel blends, including subbituminous and lower volatile coals and biomass of varying composition and combustion properties, under tight economic and environmental constraints. Since existing coalfired plants are .

Explain about functions of thermal power plant pa fan PA Fan is primary air fan which is used in power plant to push the coal from mill to furnace and to maintain the powdered coal .

process of operation of coal mill in coal based thermal power plant. ... processes of coal mill in thermal power plant devalklier. mills for coal grinding in power plant Feb 14, 2016 processes of coal mill in thermal power plant In modern thermal power plants coal grinding mills are an important and very integration of all . ...

Aug 29, 2010· Bowl mills are used for pulversing coal in pulverized coal fired boilers. The coal to the mill is fed by a coal feeder from the coal bunker. There are many type of feeders used for coal feeding like the belt feeder which can be in volumetric or gravimetric mode, the chain link feeder, the drag feeder, etc. Row coal from the yard is sized in crushers and stored in coal bunkers.

coal mill operation in power plant Coal mill pulverizer in thermal power plants SlideShare. coal mill/pulverizer in thermal power plants shivaji choudhury 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in ...

Nov 17, 2012· coal mill/pulverizer in thermal power plants shivaji choudhury 2. Coal continues to play a predominant role in the production of electricity in the world, A very large percentage of the total coal is burned in pulverized form. Pulverized coal achieved its first commercial success in .

Jun 09, 2013· MILLS IN A THERMAL POWER STATION PART I Since last 91 post i have discussed various aspect of thermal power plant .Mainly i have written my experience on civil, mechanical, boiler etc. In boiler I have discussed about structural,pressure ... EFFECTS OF COAL ELEMENT ON MILL CHOICE AND SIZING. MOISTURE More hot air is required to dry the ...

Coal Mill in Power Plant,Working Principle of Ball Mill General use of coal powder particles diameter range of 01000 um, mostly 2050 um particles, so the coal powder to make coal mill .

crushing coal grinding mill operation in power plant YouTube. Aug 9, 2014, coal grinding mill operation power plant 13 Jun 2014 crushing ce crushing coal grinding mill operation 3 days ago ce crushing coal grinding. Contact Supplier. Bowl Mills. the raw coal, so that the pulverised product at desired fineness can fed to and, operation ...

The PSEG coalfired power plant in Hamilton Township is closing June 1, 2017 because the economics of coal to generate electricity is much more expensive versus natural gas. Employee Lestor Doll (right), 54, who has worked for PSEG for 19 years, shakes hands with plant manager Jim Pfennigwerth (cq) after cleaning out his locker May 22, 2017.

Coal Mill Operation Power Plant hopeunites. Coal Mill Operation Power Plant: coal mill operation in power plant safeschoolsprogramControl for pulverized fuel coal mill IEEE Xplore. Most of the thermal power plants in the world are coal fired. Get Price And Support Online; coal mills operations dellybelly. Coal Hangup in Bowl Mill Operations.

Assistant Manager Power Plant Century Paper Board Mills June 2010 – Present 9 years 5 months. 62Km Lore Multan Highway N5, CPBM Ltd. Reporting to the General Manager, the OM will be responsible for managing the operational processes and functions required for the safe, efficient and economic operation maintenance of the power plant.

June 2008 Minhang Power Plant, Shanghai Electric Power Co., Ltd. Performance Evaluation Test Report for the ... combustion optimization system under combined operation of coal mill A and coal mill B. 4. Reference Performance test code for utility boiler GB. 5. Measuring Point, Method

Flexible Operation of CoalFired Power Plants in Germany and Flexibility Initiatives under the ... 21 June 2018 Successful ramping tests on 22 June 2018: ... Optimization of existing controls Automatic Mill Operation (Mill Scheduler) Main Steam Temperature Control Reheat Steam Temperature Control Automated Start of Fans and Pumps

WhatsApp)

WhatsApp)