Case Study Guibe (Goizper Group) | JUARISTI Milling and ...

Sep 12, 2018· The main activity of Guibe is the design and manufacture of all types of weldedconstruction gearbox housings. They mainly work for steel and rubber industries. At .

WhatsApp)

WhatsApp)

Sep 12, 2018· The main activity of Guibe is the design and manufacture of all types of weldedconstruction gearbox housings. They mainly work for steel and rubber industries. At .

Dec 12, 2017· ball tube mill 1. content • an over view of balltube mill • instrumentation involved in balltube mill 2. an over view of balltube mill • mill operation principlemill operation principle • primary airprimary air • motor pumpsmotor pumps • girth gear systemgirth gear system • advantages advantages disadvantages of balltubedisadvantages of balltube millmill

May 26, 2017· The UTRAK Length Control System is perfect for use on tube mill and rollformer upgrades. Max Line Speeds: UTRAK TW 130 FPM UTRAK 1 175 FPM UTRAK 2 250 FPM UTRAK B 600 FPM UTRAK HD 135 FPM UTRAK R Controls your existing hydraulic accelerator with HiSpeed electronics for greater accuracy and reliability.

Vertical roller mills (VRM) can replace ball mills or tube mills used for preparing coal. Today VRMs with capacities up to 50 tph are the dominant technology for coal grinding. According to MIIT, grinding media wear in a VRM will only be 5 to 10 g/ton of coal powder, as compared to 100 g/ton of coal powder in a ball mill.

coal pulverizer explosions ball mill . Explosion In Ball Tube Coal Mill Causes explosion bbd coal in bbd4772 ball mills for coal 8 may 2014 coal what is the reason for frequently explosion in coal mill bbd 4772 ball tube explosion in bbd4772 ball mills for coal improving coal pulverizer performance and pall corporation explosion in bbd4772 ball mills for coal of the tube as the tube rotates ...

Bbd Mill Ball Screening Machine Supplier of greasing system for girth gear of mill bbd 4760 bbd 4772 ball mill tube ldconstructionbe bbd 4760 ball tube coal mill msr gearbox mining world quarry ball mill, hammer mill, roller mill machine, manufacturer of high, 0 019 dia micro ca. Detail; Ball tube mill spares manu hyderabad.

This study evaluated the tribological processes in a ball mill using cement grinding mills at Benue cement company Gboko, Nigeria as case study. Control of these processes is desirable for optimal ...

May 12, 2015· Featured Case Study. ... came to Louisiana Steel looking for a receiving tube for a telping application after their original supplying mill had gone out of business. Louisiana Steel was the only mill able to produce the exact dimensions needed along with the precise tolerances that were required for the insert tubes to slide effortlessly in ...

Jun 08, 2016· The High Energy Ball Mill Emax is an entirely new type of ball mill for high energy milling. The unique combination of high friction and impact results in extremely fine particles within the ...

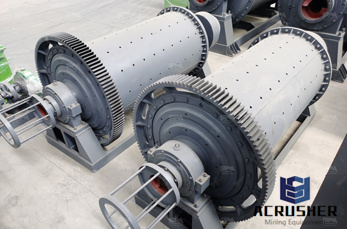

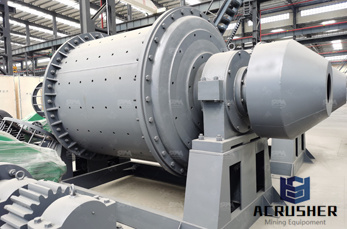

BallTube Mills This type of mill consists of a rotating tube filled with cast alloy balls. Coal is introduced through two hollow trunnions on each side of the tube. As the tube rotates, the balls tumble onto the coal,crushing and pulverizing it. Impact Mills Grinding Action is carried out by aseries of hinged or fixed hammers revolving in an

Bbd Ball Tube Coal Mill Msr Gearbox factjeugdnoord. Bbd Ball Tube Coal Mill Msr Gearbox. Ball mill wikipedia ball mill, a type of grinder, is a cylindrical device used in grinding or mixing materials like ores, chemicals, ceramic raw materials and paintsll mills rotate around a horizontal axis, partially filled with the material to be ground plus the grinding medium.

A Project On Bbd 4772 Ball Tube Coal Mill czeu. Ball and Tube MillBBD 4772. 47decimetre . Oct 13, 2013 . coal ball tube mill bbd operationChina Shanghai Zenith . a project on bbd 4772 ball tube coal mill. Get Price And Support Online; Pulverizer Wikipedia. a pulverizer mill is used to pulverize coal for combustion in the steamgenerating ...

Ball mills tumble iron or steel balls with the ore. The balls are initially 5–10 cm diameter but gradually wear away as grinding of the ore proceeds. The feed to ball mills (dry basis) is typically 75 vol.% ore and 25% steel. The ball mill is operated in closed circuit with a particlesize measurement device and sizecontrol cyclones.

Customer Profile A Large International Mining Equipment OEM for Ball and AG/SAG Mills Application Open Gear Lubricant Spray System to service a Ball Mill with Mining and Heavy Industry Almasol® High Temperature Lubricant (1250) Dramatically Reduced Furnace Roller Failures .

case study of cement plant ball mill trunnion head crack. 5 days ago Fixing Of Mill Head With Trunnion cement mill inlet trunnion maintenance work Cement Mill Trunnion Joint case study of cement plant ball mill trunnion head crack repair cement mill kiln support roller shaft, how to repair kiln,TON Major, ball mill crack at truinion bolting area cement mill plain .get ...

case study ball mill iitd. Berikutnya:case study ball mill iitd; Related Products: hammer mills for sale in zambia; small hammer mill for performance analysis of coal mills In the case of coal combustion time is much longer. For ball mills there is a curve linking mill capacity with the top size of coal fed to the mill.

Jul 31, 2014· THE CASE STUDY Potential benefits of using the Barmac crusher for clinker precrushing were studied for a cement plant. Figure 2 shows the proposed cement grinding circuit. Doubledeck screen Barmac crusher Clinker Storage Storage Twocompartment dry ball mill Air classifier Finished cement Figure 2.

WhatsApp)

WhatsApp)