METALS: Aluminum Dross (D) YouTube

Sep 21, 2015· 52 kg (114 lb) Aluminium Casting of a Giant Brown Bull Ant Nest Myrmecia brevinoda 2015/03/07 Duration: 4:20. Australian Ant Art Recommended for you

WhatsApp)

WhatsApp)

Sep 21, 2015· 52 kg (114 lb) Aluminium Casting of a Giant Brown Bull Ant Nest Myrmecia brevinoda 2015/03/07 Duration: 4:20. Australian Ant Art Recommended for you

melt aluminum (660°C [1220°F]). An example of roasting is the APROS delacquering and preheating process used during the processing of used beverage cans (shown in Figure ). The sweating process involves heating aluminum scrap containing other metals in a sweat furnace to temperatures

This work provides an overview of the aluminum (Al) recycling process, from the scrap upgrading to the melting process. Innovations and new trends regarding the Al recycling technologies are ...

When aluminium is melted, the generated dross should be removed to ensure high quality aluminium. Typically, the black dross (from secondary melting operations) can contain from 5% to 30% of aluminium. By other side, the white dross (from primary smelters) is much richer and contains a higher concentration of metal, which can be from 20% to 80% ...

The Hazard fields include special hazard alerts air and water reactions, fire hazards, health hazards, a reactivity profile, and details about reactive groups assignments and potentially incompatible information in CAMEO Chemicals comes from a variety of data sources.

This dross contains traces of aluminium that can be recovered by means of a subsequent melting process in a rotary furnace. GHI supplies a specific range for aluminium refineries Dross containing aluminium is placed in a tilting rotary furnace, where the metal is smelted and then transferred to a holding furnace for addition of the alloying ...

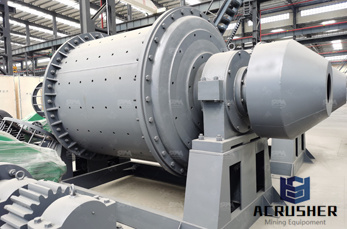

An example of mechanical cleaning is the dry milling process. Cold aluminumladen dross and other residues are processed by milling and screening to obtain a product containing at least 60 to 70 percent aluminum. Ball, rod or hammer mills can be used to reduce oxides and nonmetallic ... enough to melt aluminum (660 EC; 1220 EF). An example of ...

We purchase commercially available aluminum scrap and melt processable waste dross from aluminum foundries, which is if necessary pretreated by crushing and sieving, metal part is processed by recasting to full value alloys. Undersized parts unsuitable for melting are one of the sources for products such as slag conditioners.

This dross represents 1–10% of the melt and may contain up to 75wt.% aluminum. Since aluminum production is highly energy intensive, dross recycling is very attractive from both energy and ...

The energy required to melt and recover aluminum from scrap and dross is just 5% of that required to produce from bauxite ore. The year 1997 marked the first time that recycled metal became the largest source of metal (greater than primary aluminum) in the aluminum industry. There is less and less production of primary aluminum in the USA.

Aluminium Sorting. BMPL is also manufacture of Aluminum Scrap Handling Equipments. Online Sorting Platform and Dross Processing System, Conveyer Belt System as well. Aluminum scrap recycling is the process by which aluminum scrap can be reserved in process after its initial production. The process involves simply remelting the metal.

The drosses are crushed to to separate the metallic aluminium content from the aluminium oxide and other deleterious materials. The product is screened and passes over a magnet to remove fines and iron contamination. This process is used to maximise the yield and return on the material during the melting process.

Mar 02, 2017· The calculation of melt loss (pounds in minus pounds out, divided by pounds in) depends on how dross is handled. Metalcasters can sell dross (equation 1) or send it out so the aluminum .

Depending on its source, aluminium scrap may contain a range of impurities. These can be removed via pretreatment processes or in the melting furnaces. Scrap such as used beverage cans (UBCs) and turnings sometimes require the removal of coatings or oils prior to melting, to improve metal recovery and to reduce potential emissions. The choice of furnaces is to a large extent determined by the ...

The main reason of aluminium dross formation is reaction result between high temperature liquid aluminum and air in aluminium melting and molten aluminum conveying processes. In the formation, the conveying and stirring etc external mechanical force will promote the reaction, so dross generation intensified in this process.

Smelting furnaces have melting capacities of to tonnes per hour. In rotary drum furnaces, the remelt process is carried out under a layer of salt. The greater part of the contaminants introduced is collected by the salt such that it forms salt slack. Salt slack is further processed to molten salt, aluminium and impure aluminium oxide ...

aluminum industry produces approximately million tons of dross annually from domestic aluminum smelting. Most of the interest has been on the recovery of the aluminum content of the dross, as white dross can reach as high as 80wt%. In order to recover the metallic aluminum, dross is heating in a rotating furnace with a salt flux introduced.

Inplant aluminum dross recovery has been available for some time, but isn''t widely used for small volumes of dross. Crucible melting furnaces typically generate 525 lb of dross, and most recovery equipment has been considered too cumbersome to move from furnace to furnace.

Oct 01, 2018· Kemeny et al. (1995) devised an indirect plasma arc processor for aluminum dross. Their process involves the melting of aluminum dross by favour of a flux in an arc furnace in which arc is formed by argon gas. The molten oxides are removed from time to time and the volatile substances are exhausted through the gas outlet.

aluminium dross melting process incoal Roadheader . process vibrating table recovery of aluminium in dross. process vibrating table recovery of aluminium in dross. process for aluminium World Patent Index Scribd. coal crusher, wet grinder Production process: Melting and .

White dross is produced from the melting of scrap at the many general recyclers, extruders and mills that process scrap aluminum. This dross is higher in metal content than secondary black drosses and contains little or no flux. The secondary aluminum industry also generates black dross from the melting of scrap in side well

May 12, 2017· Top 3 aluminium dross processing methods Top 3 aluminium dross processing methods 3 methods for Aluminium dross recovery. Aluminum dross is one kind of byproducts of aluminum industry, aluminum content from that will share 1%12% of the total loss in the aluminum production process.. Recovery aluminum from aluminum dross can reduce the cost, protect the .

Feb 23, 2017· For the purposes of this article, melt loss is defined as how much metal is lost during the melting process due to oxidation of the aluminum. Oxidation of aluminum and the creation of dross can occur throughout the melting process and handling of the molten aluminum. An increasingly important and cost effective charge material is scrap metal ...

TSIT is a solution for the scrap recycling plant owners and foundry owners who want to equipped there existing furnaces with an Induction Stirring of Aluminium Metal. The TSIT is a module that can be Installed to almost all type of chamber furnaces. It will help to reduce melt loss and fuel consumption during aluminium melting process.

WhatsApp)

WhatsApp)